Audioquest Mackenzie/709 (Pair) RCA or XLR

Mackenzie RCA or XLR (Pair)

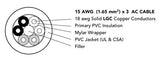

The Mackenzie/709 cable.

- SOLID PERFECT-SURFACE COPPER+ (PSC+) CONDUCTORS

- NITROGEN-INJECTED HARD-CELL FOAM INSULATION

- CARBON-BASED 3-LAYER NOISE-DISSIPATION SYSTEM (NDS)

- TRIPLE-BALANCED GEOMETRY

- 709 RCA or Cannon XLR Plugs

We take the Mackenzie cable and terminate it with the high quality Audioquest 709 RCA plugs. These plugs are comparable quality with what normally comes on the Mackenzie cable. They are terminated by hand with the WBT solder. The 709 is a 3 piece plug with the same design that's used on the more expensive cables in Audioquests' line of cables. If you order the XLR version, we terminate the cables with the high quality Cannon silver plated XLR plugs. (See the link below for information on these plugs.) They have the braided jacket.

Click here for Cannon XLR Plug information: https://en.wikipedia.org/wiki/ITT_Interconnect_Solutions

These cables are personally terminated by Harry, (The “H” of HCM Audio). Harry has been professionally terminating cables for over 40 years. He takes extreme care that no conductors are nicked during termination. Each cable is hand tested and sealed in a plastic bag.

SOLID PERFECT-SURFACE COPPER+ (PSC+) CONDUCTORS: Perfect-Surface Copper+ has an astonishingly smooth and pure surface. Proprietary metal-processing technology protects the wire’s surface at every stage of drawing and fabrication. When high-purity low-oxide copper is kept as soft, pure and smooth as possible, it becomes a wonderfully low-distortion PSC+ conductor. PSC+ is manufactured by applying the same exceptional technology to an ultra-pure copper. The resulting sound quality is even more focused and simply less in the way. For over 30 years AudioQuest has pioneered the use of superior metals; yet even we were surprised by the huge leap in performance made possible with Perfect-Surface Technology. PSC+ simply outperforms all previously available copper metals at any price. All of Mackenzie’s conductors are solid. Electrical and magnetic interaction between strands in a conventional cable is the greatest source of distortion, often causing a somewhat dirty, harsh sound. Solid conductors are fundamental toward achieving Mackenzie’s very clean sound.

NITROGEN-INJECTED HARD-CELL FOAM INSULATION: Nitrogen-Injected Hard-Cell Foam insulation is used exclusively in most of AudioQuest’s video and digital audio cables. Similar to Foamed-PE, it is nitrogen-injected to create air pockets. ‘Hard’ foam is used because the stiffness of the material allows the conductors in the cable to maintain the same relationship with each other along the full length of the cable, thus ensuring that the characteristic impedance of the cable is consistent.

CARBON-BASED 3-LAYER NOISE-DISSIPATION SYSTEM (NDS): 100% shield coverage is easy. Preventing captured RF Interference from modulating the equipment’s ground reference requires AQ’s Noise-Dissipation System. Metal and Carbon-Loaded synthetics prevent most RFI from reaching the equipment’s ground plane.

TRIPLE-BALANCED GEOMETRY: The three conductors in “Triple-Balanced” Mackenzie cables ensure that whether prepared with RCA or XLR plugs, the positive and negative signals have equally low-distortion conducting paths. The 100% coverage shield is never used as an inferior conductor.